What the Best Weight for a Pinewood Derby Car

How to Build the Fastest Pinewood Derby Car

Follow this article for the secrets to the ultimate Pinewood Derby car.

![]() Time

Time

A few hours

![]() Complexity

Complexity

Beginner

![]() Cost

Cost

$20-50

Introduction

We'll tell you our favorite tricks and tips and give you the basic physics behind why they work.

Tools Required

Materials Required

- Graphite

- Official Grand Prix Pinewood Derby Kit

- Sandpaper

- Tungsten weights

- Wood filler

Below are the regulations most Pinewood Derbies follow, referred to as the "Rules in the Box." It's very important to follow these rules because if even one is broken, you'll have a sad kid on your hands and lots of wasted time and energy. Not all Pinewood Derbies are the same so make sure to check with your local Scout District/Council rules to see if anything is different.

- Car Specifications: Width: 2-3/4"; Length: 7"; Weight: Maximum of 5 Ounces; Width between wheels: 1-3/4"

- The car must have been made during the current year (year in which derby is being held). Cannot use previous years cars.

- Wheel bearings, washers, and bushings are prohibited.

- The car shall not ride on springs.

- Only official Cub Scout Grand Prix Pinewood Derby wheels and axles are permitted.

- Only dry lubricant is permitted.

- Details, such as steering wheel and driver are permissible as long as these details do not exceed the maximum length, width and weight specifications.

- The car must be free-wheeling, with no starting devices.

- Each car must pass inspection by the official inspection committee before it may compete.

- If, at registration, a car does not pass inspection, the owner will be informed of the reason for failure and will be given time within the official weigh-in time period to make the adjustment.

After final approval, cars will not be re-inspected unless the car is damaged in handling or in a race. Plus: Check out some brilliant woodworking tips for beginners here.

Project step-by-step (9)

Step 1

Bake the block

Wood holds water, and water adds weight. We want weight, but we want the weight where it's most beneficial. Pre-heat your oven to 250 degrees, then bake your block for 2 hours. All the water evaporates, allowing more control during the next few steps.

Step 2

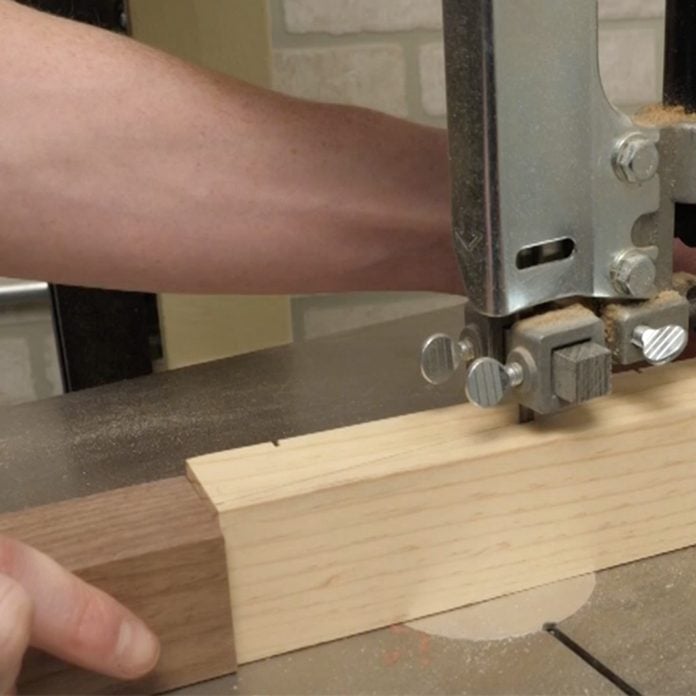

No fancy shapes

Once your block is dried, most people want to cut it into an interesting shape, maybe make it into the profile of your dream car. But aerodynamics rule the day, and the best shape is a simple wedge. Just like a spoiler on the rear of a sports car, the wedge shape allows as much air to flow over the top of the car without hinderance while keeping the car pinned to the track. Our wedge tapers from 5/16-in. to 7/8-in. A bandsaw and push stick are the quickest way to cut the wedge (wear safety gear and follow safety guidelines), but a coping saw works just fine. Sand the car body up to 220-grit.

Sign Up For Our Newsletter

Complete DIY projects like a pro! Sign up for our newsletter!

Do It Right, Do It Yourself!

![]()

Step 3

Not all wedges are created equal

Another name for this section could be 5 oz. doesn't always equal 5 oz. The heavier your car is, the faster it'll be. It's the location of the weight that makes the difference. The ideal placement for the center of gravity is 7/8-in. in front of the rear axle. Too far forward and you'll lose potential energy (P=9.8mh or the energy caused by the item's position). Too far back and your car will pop a wheelie, ruining any chance for a win. To make sure your car doesn't exceed the weight limit, weigh all the parts before assembly. Leave a little wiggle room for paint, glue, stickers, etc.

Tungsten is the best weight because it's heavy for its volume, allowing more precise placement. You can purchase it on Amazon by clicking here.

Step 4

Engineer the wheels

This is one of those borderline illegal steps (Remember, a Scout is honest). Double check with your local rules to make sure that it's allowed. A lighter wheel increases your kinetic energy (K=1/2mv2 or the energy a body possess by virtue of being in motion). The best way to decrease wheel weight is to sand the wheels as smooth as possible, rounding any sharp surfaces. Also, most wheels aren't perfectly round right out of the package so getting them as round as you can helps a lot. Some people buy wheels separately and match the mold number on the inside of the wheels for consistency. Others polish the inside hub using toothpaste on a pipe cleaner to remove any imperfections in the plastic.

Step 5

Smooth the axles

The stick nail axles included in the kit have little ribs along the shank and a flat nail head, both of which cause friction, slowing the wheels. Smooth the axles by chucking them into a drill press and sanding them up to 2000 grit. With the nail still in the drill press, round the inner face of the nail head with a file and sand it smooth. Secure the axles to the car body, add graphite, spin the wheels and time the spin duration. A good axle set up will spin for about 45 seconds.

You can purchase hand-machined, legal axles on Amazon: Click this link to find them.

Step 6

Ride on three wheels if allowed

To reduce even more friction against the track, raise one of the front wheels just slightly higher than the other so that it doesn't touch the track. If you try this step, the center of balance needs to be exactly down the centerline of the body so that the car doesn't wander on the track. Again, check with your local rules to see if this is allowed.

Step 7

Graphite, graphite, graphite

Because only dry lubricant is allowed, the solution most people agree upon is graphite. Where do you use the graphite? Everywhere; wheels, axles, axle slots. The type of graphite doesn't matter. It all works, so buy the cheap stuff. Spin each wheel numerous times to help the graphite break down for maximum performance.

Step 8

Cover the wheels

Much like the first step, this is an aerodynamics lesson. Exposed wheels allow air to flow over the front and then get caught under the rear. Next time you're driving, notice how many exposed wheels are on the road. None. To make "fenders", outline their shape and mark the wheel centers on 1/2 in. pine. Drill a hole with a 1-1/4 in. Forstner bit at the wheel center, and then cut out the rest of the shape with a handsaw. Glue the fenders to the body.

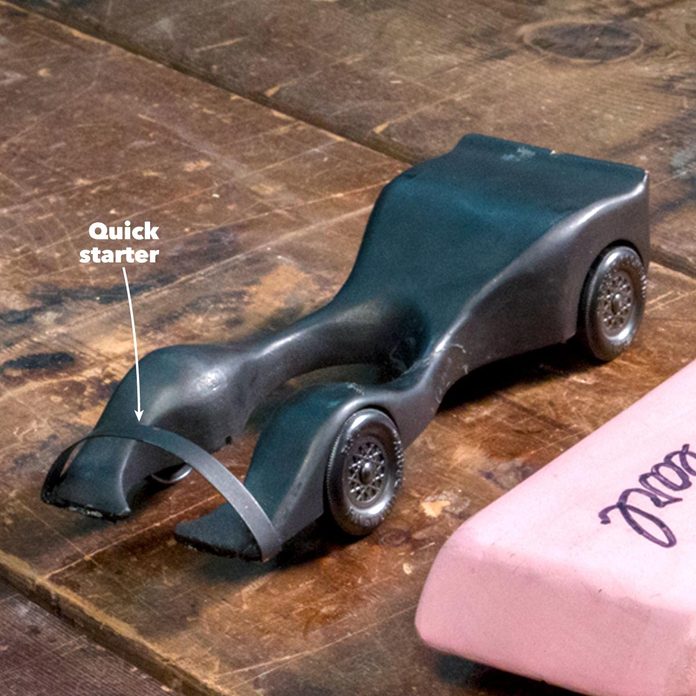

Step 9

Quick Starter

Most derby cars are designed so they don't start until the starting pin fully drops. But there's a simple way to let the car start inching forward while the pin is moving, giving you a head start. Unfold a paper clip, making it a three-sided rectangle. Mark and drill hole locations on the front end of the car, ensuring that once assembled, the paperclip doesn't extend past the front of the car. Drill 1/4-in. into the body and glue the paperclip ends into the holes with CA glue. Next, check out some of our favorite woodworking projects to do indoors.

Every product is independently selected by our editors. If you buy something through our links, we may earn an affiliate commission.

What the Best Weight for a Pinewood Derby Car

Source: https://www.familyhandyman.com/project/how-to-build-the-fastest-pinewood-derby-car/

0 Response to "What the Best Weight for a Pinewood Derby Car"

Post a Comment